Got the top and bottom yokes finished.

Drag bars fitted to the top yoke with alloy risers

and stops fitted to the bottom yoke.

Sunday, 29 March 2015

Friday, 27 March 2015

Modifying the Yoke Part 2

Measured up the top yoke for the new bars.

I have decided not to run the standard aprilia

bars instead to go with risers and drag/flat bars.

Again planning the holes to avoid the webs underneath.

Bought set of cheap aluminium risers off e-bay

which come with odd-ball M7 bolts.

I have decided not to run the standard aprilia

bars instead to go with risers and drag/flat bars.

Again planning the holes to avoid the webs underneath.

Bought set of cheap aluminium risers off e-bay

which come with odd-ball M7 bolts.

Labels:

Aprilia Yokes,

Top yoke

Modifying the Yoke

Started with the front end: the bars and stops.

I measured the bottom yoke for the stops.

Trying to locate them to avoid the webs

underneath and achieve a good angle.

I measured the bottom yoke for the stops.

Trying to locate them to avoid the webs

underneath and achieve a good angle.

Labels:

350 F2 Frame,

Aprilia Yokes,

bottom yoke,

steering stops

Wednesday, 25 March 2015

Side Stand Sorted

Modified side stand to relocate the original spring and

Shortened the kick tab, both the tab and the foot do not

interfere with the gear change lever.

Shortened the kick tab, both the tab and the foot do not

interfere with the gear change lever.

Labels:

350 F2 Frame,

Side Stand

Tuesday, 24 March 2015

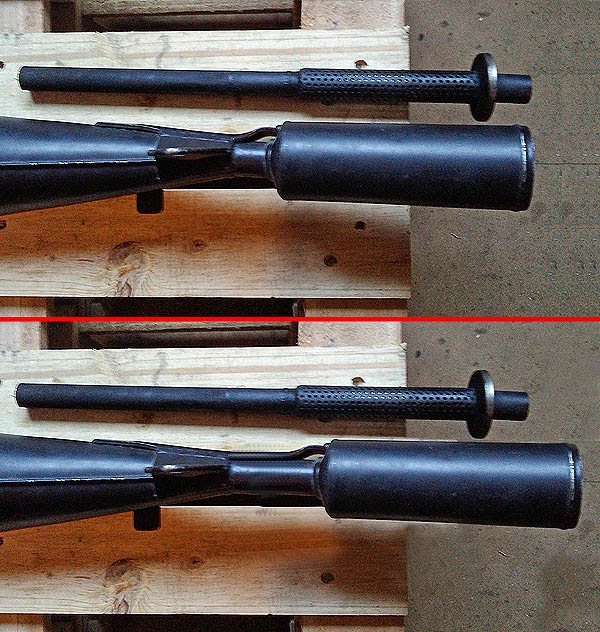

Left Pipe Extended

I took the plunge and cut the end can off the

left hand exhaust. This enabled me to mount

the main body of the exhaust to the engine/frame

to check the side stand clearance and spring

location.

The end can will have to be extended by a minimum

of 125mm to clear the swingarm. The image below

shows it extended fully by about 200mm. This also

places it wider than before.

left hand exhaust. This enabled me to mount

the main body of the exhaust to the engine/frame

to check the side stand clearance and spring

location.

The end can will have to be extended by a minimum

of 125mm to clear the swingarm. The image below

shows it extended fully by about 200mm. This also

places it wider than before.

Labels:

350 F2 Frame,

Codnor Micron,

Exhaust

Friday, 20 March 2015

End Can Extender

Another option and probably a more suitable one

is to extend the end can past the point of contact with

the swingarm. Photoshop estimation below.

is to extend the end can past the point of contact with

the swingarm. Photoshop estimation below.

Labels:

Codnor Micron,

Exhaust

Thursday, 19 March 2015

Exhaust Run Fine Tune

In order to get the side stand clearances sorted

the Exhaust run really has to be finalised.

I cut a length of pipe to simulate the header length

and offered it up to see how the exhaust on the left

sat. There are two issues,

[1.] the inside rib on the Micron exhaust clashes with

the cross bar of the frame but this can be ground

down to clear in that particular spot and welded to

re-seal if needed, this will also have to be done with

the right side too.

[2.] the end can as mentioned before clashes with the

swinger which is wider on the left for the chain run.

I am planning to slice a piece off the inside at a

straight angle and weld a flat piece back on. This will

only affect the padding inside and not the baffle itself.

it shouldn't be too much to remove, approximately

20mm in and about 50mm in length . . .

the Exhaust run really has to be finalised.

I cut a length of pipe to simulate the header length

and offered it up to see how the exhaust on the left

sat. There are two issues,

[1.] the inside rib on the Micron exhaust clashes with

the cross bar of the frame but this can be ground

down to clear in that particular spot and welded to

re-seal if needed, this will also have to be done with

the right side too.

[2.] the end can as mentioned before clashes with the

swinger which is wider on the left for the chain run.

I am planning to slice a piece off the inside at a

straight angle and weld a flat piece back on. This will

only affect the padding inside and not the baffle itself.

it shouldn't be too much to remove, approximately

20mm in and about 50mm in length . . .

Labels:

Codnor Micron,

Exhaust

Friday, 13 March 2015

Exhaust Run

temporarily fitted the pipes to check clearances

here is how it should look . . .

because the exhaust ports are angled inwwards

it looks like the cans will clear the swingarm.

here is how it should look . . .

because the exhaust ports are angled inwwards

it looks like the cans will clear the swingarm.

Labels:

350 F2 Frame,

Codnor Micron,

Engine,

Exhaust,

RD250

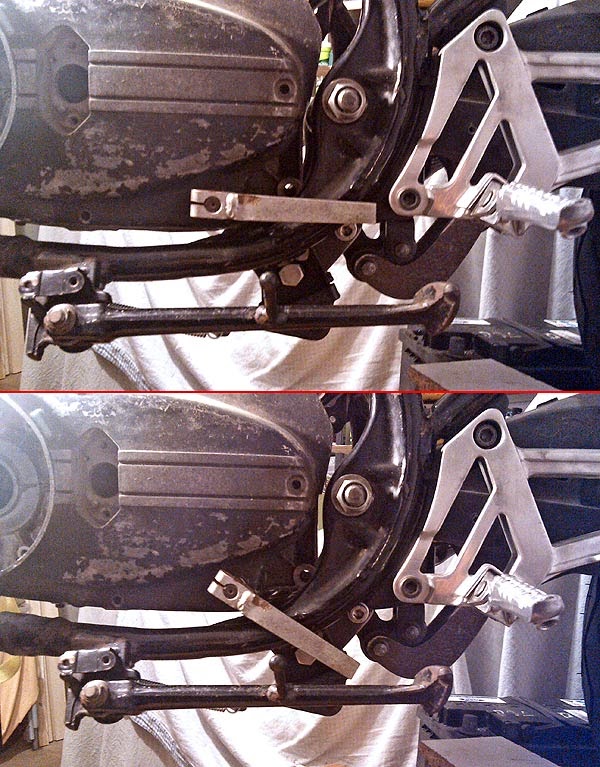

Gear Change

More side stand ponderings

there will have to be a few tweaks to the side stand.

it turns out the point where the spring is held

on the stand hits the exhaust along with the spring.

I know I have the original spring in the garage

somewhere, i put it somewhere safe, as usual too safe.

this would be a better fit as the spring part of it does

not run the full length link the temporary one in the image.

the gearchange is ok but the kick peg on the side

will have to be moved.

there will have to be a few tweaks to the side stand.

it turns out the point where the spring is held

on the stand hits the exhaust along with the spring.

I know I have the original spring in the garage

somewhere, i put it somewhere safe, as usual too safe.

this would be a better fit as the spring part of it does

not run the full length link the temporary one in the image.

the gearchange is ok but the kick peg on the side

will have to be moved.

Labels:

350 F2 Frame,

Exhaust,

Side Stand

Wednesday, 11 March 2015

Freestanding

no need for belts or straps . . .

managed to fit a side stand last night. I had one

from a Honda CBR-600 "in stock" which just

bolts on after a slight modification to the outer

diameter of the mounting surface where a sensor

fits on the CBR stand.

I need to check that the gear linkage and footrest

clear the folded stand . . . looks a bit close . . .

managed to fit a side stand last night. I had one

from a Honda CBR-600 "in stock" which just

bolts on after a slight modification to the outer

diameter of the mounting surface where a sensor

fits on the CBR stand.

I need to check that the gear linkage and footrest

clear the folded stand . . . looks a bit close . . .

Labels:

350 F2 Frame,

Side Stand

Tuesday, 10 March 2015

Rear Engine Mount

I decided to use the existing rear engine mounts

on the F2 frame but while the engine mount

lines up perfectly with the existing frame mount

on the left hand side the bolt holes do not line up.

A few 5mm thick steel mounts were fabricated and

welded with an aluminium spacer to fix the engine

to the frame. I just need to get a "Half Nut" and a

correct length bolt to finish the job.

on the F2 frame but while the engine mount

lines up perfectly with the existing frame mount

on the left hand side the bolt holes do not line up.

A few 5mm thick steel mounts were fabricated and

welded with an aluminium spacer to fix the engine

to the frame. I just need to get a "Half Nut" and a

correct length bolt to finish the job.

Labels:

350 F2 Frame,

Engine mounts,

RD250

Monday, 2 March 2015

Sunday, 1 March 2015

Engine Frame Clearance

In order for the engine to clear the frame in all areas

it had to be lifted at the rear by approximately 7mm.

Next up is to make some top rear mounts brackets using the existing

mounting points.

it had to be lifted at the rear by approximately 7mm.

Next up is to make some top rear mounts brackets using the existing

mounting points.

Labels:

350 F2 Frame,

Engine mounts

Engine Mounts final

Front engine mounts welded into place and primer

coated to combat the surface rust building up in my garage.

So engine in and lined up. I had concerns about the swingarm

angle and the relation between the final drive and the swingarm

pivot point. The engine has ended up a little lower than desired

this will have to be a compromise.

The swingarm angle is set approximately at 12.5 degrees which

I read somewhere that it was a desirable number.

coated to combat the surface rust building up in my garage.

So engine in and lined up. I had concerns about the swingarm

angle and the relation between the final drive and the swingarm

pivot point. The engine has ended up a little lower than desired

this will have to be a compromise.

The swingarm angle is set approximately at 12.5 degrees which

I read somewhere that it was a desirable number.

Subscribe to:

Comments (Atom)