I picked up the pipes from the welders on Friday

and test fitted them, Fit perfect!

Next on the list is a big cleanup in the garage

and get the gear change linkage fitted then fit

the electrics and loom.

Showing posts with label Codnor Micron. Show all posts

Showing posts with label Codnor Micron. Show all posts

Monday, 29 June 2015

Thursday, 18 June 2015

Pipe ready for Welding

After sourcing a suitable length of pipe with

the correct bore I cut a section with angled ends

to extend the end can of the left pipe to clear the

swingarm. The end can will be extended by about

70mm. The original internal stinger has been cut

to be welded in place where it would normally be

with the other end with the silencer being able to

fit back into the end can. The stabilizer strap will

have to be remade to span across the 3 sections

of pipe.

The images below show the pipes taped up to give

an impression of the layout/run of the pipe. [its a bit saggy!]

the correct bore I cut a section with angled ends

to extend the end can of the left pipe to clear the

swingarm. The end can will be extended by about

70mm. The original internal stinger has been cut

to be welded in place where it would normally be

with the other end with the silencer being able to

fit back into the end can. The stabilizer strap will

have to be remade to span across the 3 sections

of pipe.

The images below show the pipes taped up to give

an impression of the layout/run of the pipe. [its a bit saggy!]

Labels:

Codnor Micron,

Exhaust

Sunday, 7 June 2015

Exhaust run

I made a start today about stripping the frame totally while

the front end was off. I flipped the frame and installed the

engine cases with the barrels and heads in order to finalise

a solution for the left side exhaust pipe. I think I have

sourced a suitable bit of mild steel pipe to extend the

silencer past the swingarm.

the front end was off. I flipped the frame and installed the

engine cases with the barrels and heads in order to finalise

a solution for the left side exhaust pipe. I think I have

sourced a suitable bit of mild steel pipe to extend the

silencer past the swingarm.

Labels:

Codnor Micron,

Exhaust

Tuesday, 24 March 2015

Left Pipe Extended

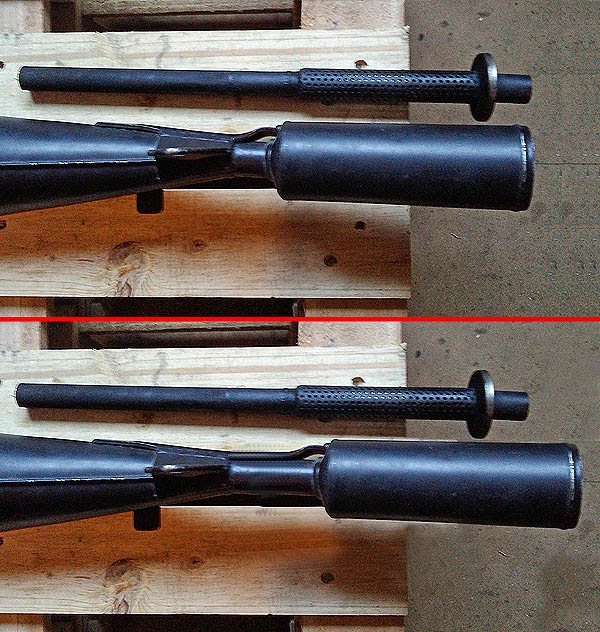

I took the plunge and cut the end can off the

left hand exhaust. This enabled me to mount

the main body of the exhaust to the engine/frame

to check the side stand clearance and spring

location.

The end can will have to be extended by a minimum

of 125mm to clear the swingarm. The image below

shows it extended fully by about 200mm. This also

places it wider than before.

left hand exhaust. This enabled me to mount

the main body of the exhaust to the engine/frame

to check the side stand clearance and spring

location.

The end can will have to be extended by a minimum

of 125mm to clear the swingarm. The image below

shows it extended fully by about 200mm. This also

places it wider than before.

Labels:

350 F2 Frame,

Codnor Micron,

Exhaust

Friday, 20 March 2015

End Can Extender

Another option and probably a more suitable one

is to extend the end can past the point of contact with

the swingarm. Photoshop estimation below.

is to extend the end can past the point of contact with

the swingarm. Photoshop estimation below.

Labels:

Codnor Micron,

Exhaust

Thursday, 19 March 2015

Exhaust Run Fine Tune

In order to get the side stand clearances sorted

the Exhaust run really has to be finalised.

I cut a length of pipe to simulate the header length

and offered it up to see how the exhaust on the left

sat. There are two issues,

[1.] the inside rib on the Micron exhaust clashes with

the cross bar of the frame but this can be ground

down to clear in that particular spot and welded to

re-seal if needed, this will also have to be done with

the right side too.

[2.] the end can as mentioned before clashes with the

swinger which is wider on the left for the chain run.

I am planning to slice a piece off the inside at a

straight angle and weld a flat piece back on. This will

only affect the padding inside and not the baffle itself.

it shouldn't be too much to remove, approximately

20mm in and about 50mm in length . . .

the Exhaust run really has to be finalised.

I cut a length of pipe to simulate the header length

and offered it up to see how the exhaust on the left

sat. There are two issues,

[1.] the inside rib on the Micron exhaust clashes with

the cross bar of the frame but this can be ground

down to clear in that particular spot and welded to

re-seal if needed, this will also have to be done with

the right side too.

[2.] the end can as mentioned before clashes with the

swinger which is wider on the left for the chain run.

I am planning to slice a piece off the inside at a

straight angle and weld a flat piece back on. This will

only affect the padding inside and not the baffle itself.

it shouldn't be too much to remove, approximately

20mm in and about 50mm in length . . .

Labels:

Codnor Micron,

Exhaust

Friday, 13 March 2015

Exhaust Run

temporarily fitted the pipes to check clearances

here is how it should look . . .

because the exhaust ports are angled inwwards

it looks like the cans will clear the swingarm.

here is how it should look . . .

because the exhaust ports are angled inwwards

it looks like the cans will clear the swingarm.

Labels:

350 F2 Frame,

Codnor Micron,

Engine,

Exhaust,

RD250

Wednesday, 15 May 2013

blow out

next step was to apply heat to the damaged areas with the aid of 2 butane/propane blow torches to soften them metal for the internal air pressure to push out the dented areas.

I got the first pipe fairly well sorted with a few of the deeper scores still visible, The second pipe was more of a challenge as the damage was greater . . . and I ran out of gas!

I got the first pipe fairly well sorted with a few of the deeper scores still visible, The second pipe was more of a challenge as the damage was greater . . . and I ran out of gas!

Labels:

2 Stroke,

Codnor Micron,

Exhaust,

Yamaha Engine,

Yamaha RD-250

pumped

Next step was to plug both ends of each pipe after removing the baffles pressurized with air from a foot pump.

I used 5mm steel plate and an old bicycle tube as a seal with various brackets and clamps. I was able to get the pressure up to 80psi.

I used 5mm steel plate and an old bicycle tube as a seal with various brackets and clamps. I was able to get the pressure up to 80psi.

Labels:

2 Stroke,

Codnor Micron,

Exhaust,

Yamaha Engine,

Yamaha RD-250

compressed expansions

A major concern for me was the whole topic of the expansion chambers, firstly sourcing a set and secondly fitting them with the non native frame present.

I managed to source a set from a forum member on RDnuts . they are a pair of early Microns under the name "Codnor Micron" with short can silencers. They have been involved in a meeting with a foreign object at the diffuser point and need to be repaired.

I managed to source a set from a forum member on RDnuts . they are a pair of early Microns under the name "Codnor Micron" with short can silencers. They have been involved in a meeting with a foreign object at the diffuser point and need to be repaired.

Labels:

2 Stroke,

Codnor Micron,

Exhaust,

Yamaha Engine,

Yamaha RD-250

Subscribe to:

Posts (Atom)